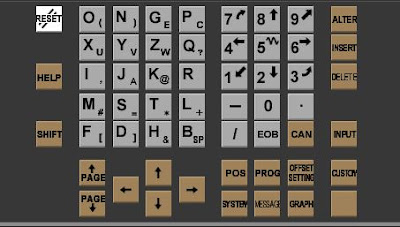

FUNCTION OF MDI

PANEL KEYS

CNC machines need to perform many different operations as

needed, many types of keys have to be used on the computer control panel to

perform this type of operation. But it has to use key on the control panel to

perform special functions .Any key function on the control panel is different

.To operate the CNC you should know the name of each key and their function

.The function of each key on the CNC MDI panel is as follows.

Address and Numeric keys

1) A to Z (Address key )

- This key is used to type the

address code into the program

2)NUMBER KEYS - These keys allow numeric entry.

Normally located close to the letter keypad, most CNC controls have number keys

positioned .

3)EOB

KEY - This key is used

when complete the one block with a symbol at the end(;) .

4) CAN KEY -This KEY is used to

cancelled the missed code while typing the program.

5) DELETE KEY - This key is

used to remove the code or block from the program.

6) INSERT KEY - This key is

used to put the typed code into the program in write mode .

7) ALTER

KEY - This key is used

to replace the other code with the one in the program.

8) SHIFT KEY - This key is used to

hold the lowercase letter on the address key . That is,

if we assume that we want the small letter V in the Y tab above the address key,

then we have to press Shift + Y= V.

if we assume that we want the small letter V in the Y tab above the address key,

then we have to press Shift + Y= V.

9) INPUT TAB - This key is

used to input the parameter of offset or setting.

10) CURSOR

UP /DOWN KEY - This key is

used to move the cursor up & down within

the program

the program

11) PAGE UP/ DOWN KEY - If the program is of multiple

pages, then this key is used to

jump to the top or bottom page.

jump to the top or bottom page.

12) RESET KEY - This key is used to clear the alarm when typing a

program.

13) MESSAGE KEY - This key is use ,when an

alarm arrives, it checks to see which

message the system came from

message the system came from

Function key's

1)CONTROL

ON / DRIVE ON - This key is used to turn ON the computer MDI panel.

2) CONTROL OFF – This key is used to turn OFF

the computer MDI panel.

3)EMERGENCY STOP - This key is used immediately to prevent Machine from

damaging the machine if it is

misbehaving.

4)PROG(Program) -This key is used to view the store program or

to insert it into

the new program system.

5) POS - Use this key to check the machine's axis

position.

6) OFFSET - Use this key to set offset all types of tool

jobs.

7) DGONS PARAM (Diagnosis

Parameter )- This key is used to change the computer

parameters and maintain it.

8) SYSTEM - This key is used to view files in the system.

9) AUX GRAPH/GSTM - Use this key to

test the program or to test the tool path through

a graph.

10)

OPT STOP - If the M01 code is inserted in the program,

then it is kept on .

11)Z- AXIS LOCK - This key is used if you want to disable axis

in the program.

12)M/C LOCK -This key is used to close all axis.

13)AUX LOCK - This key was used to stop the function of

the code.

14) SPDL ON - This key is used to turn ON the spindle

.

15)

SPDL OFF - This key is used to turn OFF

the spindle.

16) SPDL DEC/INC - This key is used to decrease /increase the

spindle speed.

17)FEED ON /OFF - This key is used

to turn ON/OFF the feed rate.

18)TOOL DECLAMP - This the key is used to remove the tool in Turret.

19) FEED OVERRIDE - This key is used to high & lower the feed rate percentage.

20) CYCLE START /STOP – This key is used to start / stop the program .

18)TOOL DECLAMP - This the key is used to remove the tool in Turret.

19) FEED OVERRIDE - This key is used to high & lower the feed rate percentage.

20) CYCLE START /STOP – This key is used to start / stop the program .

Mode

Key’s

1)

REF (Reference ) - This key is used to pass

the reference position to all Axis.

2) JOG – This key is used to run manually axis .

3) EDIT- This key is used to editing in program.

4) MDI or MDA(Manual data input ) – This key is

used for three function Home position,

tool indexing, spindle rotation.

5) INC JOG – This key is used to run axis in micron like 1 , 10 ,

100 , 1000 .

6) AUTO (Automatic ) – This key is used to run a program in automatic

.

7) MODE CNC – This key is kept on for

run machine operation.

8) DNC - This key is used to import programs from outside the

computer.

9) DRN (Dry run ) – In this mode, the program

executes the commands

given in the program rapidly to

check.

10 )SBL – This key is used to run a program block one by one.

11) BDL – This key is used to delete the block in the program .

12)MPG (Manual pulse generator )- In this mode, with the help of a hand wheel,

the servo motor operates the axis by manually pulse supply. In this model

the Axis can be easily moved to 1 micron.

FUNCTION OF CNC CONTROL PANEL KEYS

Reviewed by www.cncknowledge.in

on

April 16, 2020

Rating:

Reviewed by www.cncknowledge.in

on

April 16, 2020

Rating:

Reviewed by www.cncknowledge.in

on

April 16, 2020

Rating:

Reviewed by www.cncknowledge.in

on

April 16, 2020

Rating: